Manage Orders

Manufacturing orders

Manage your products into assembly lines or manual assembly.

Work orders

Launch production of items needed in the final assembly of your products

Unbilled orders

Disassemble a finished product and recuperate components.

Repair orders

Manage repairs of items under warranty or as a service.

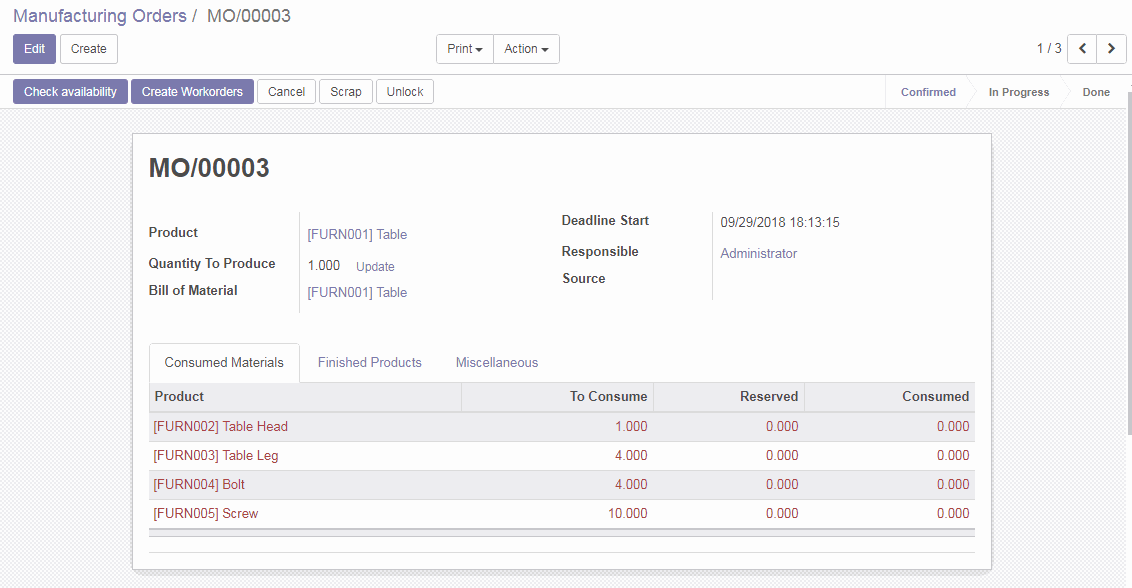

Editable MOs

You are now able to consume other products despite what was initially planned and edit MOs once they are done.

Schedule & Plan

Hierarchies of cost accounts

Get a clear view on your whole planning and easily reschedule manufacturing

Organize work orders

Have access to all available resources and plan ahead with your production.

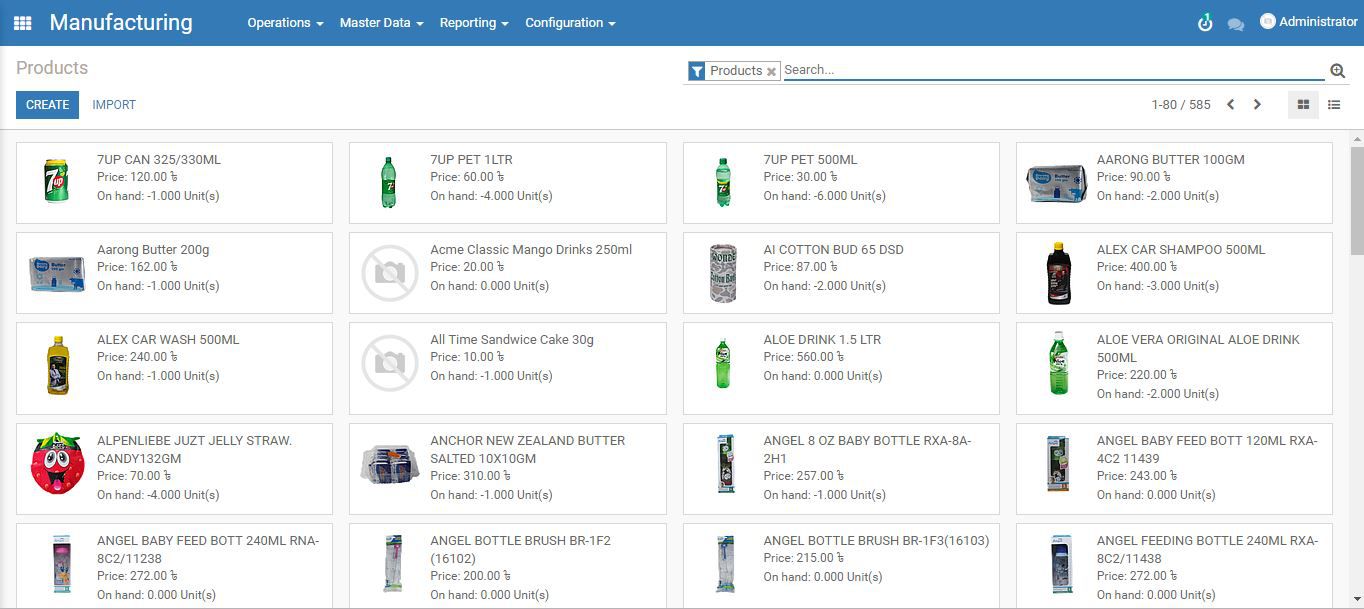

Manage Bill of Materials

Keep track of availability of items in stock and production time

Workcenter Capacity

MRP II scheduler using capacities and schedules of workcenters.

Flexible Master Data

Create multi-level Bills of Materials

Set a Bill of Materials within another in order to manufacture components of a product in another Bill of Materials.

Optional routing

Create new routings for work orders in order to sequence your production depending on the routing used.

Version changes

Allow your products to evolve and add configurable options when creating orders.

Kits

Odoo's kitting features allows your salesperson to sell a kit, but you will deliver a set of products.

PLM

Versioning

Easily get differences between versions to track changes.

PLM

Track versions of products and ECO's as well as their respective documents. Merge different ECO's corresponding to the same BoM.

Engineering Changes

Track changes with a great kanban process for ECOs.

Document Management

Store plans and worksheet directly on bill of materials and routings.

Quality

Control Points

Automatically trigger quality checks for the manufacturing department.

Quality Checks

Deploy your statistical process control easily with checks.

Quality Alerts

Organize your work using the kanban view of quality alerts.

Maintenance

Preventive Maintenance

Trigger maintenance requests automatically based on KPIs.

Corrective Maintenance

Trigger corrective maintenance directly from the control center panel.

Calendar

Schedule maintenance operations with a calendar.

Statistics

Get all maintenance statistics computed for you: MTBF,...

Workcenter Control Panel

Tablets

Set tablets on every work center to organize their work efficiently.

Record production

Register productions, scan products, lots or serial numbers.

Worksheets

Display worksheets directly on the workcenter with instructions for operator.

Misc Operations

Scrap products, create quality alerts, perform checks, right from the workcenter.

Alerts

Use alerts to show changes or quality checks to the operator.

Work order steps

Define multiple steps in a workorder and link them to worksheet pages: scan a product, take a picture, quality control, etc.

Want to know more? Take a Tour!